Single-use plastic packaging is anticipated to grow by 6.1 per cent globally this year, driven by the e-commerce, healthcare and food and beverages sectors in key high-growth Asian markets such as India, China and Indonesia.

A shopfront in Bali, Indonesia, selling single-use plastic packaged products. Asia Pacific is dominating the market share of the global single-use plastics packaging market.

Single-use plastic packaging is expected to be a US$26 billion global industry this year, with rapid market growth driven by rising spending power in Asia Pacific, according to new analysis.

The market for throwaway plastic is anticipated to expand by 6.1 per cent in 2023, and is projected to be worth US$47 billion by 2033, the study by Dubai-based intelligence and consulting firm Future Market Insights finds.

The durability, flexibility, convenience and low cost of disposable plastics have led to their widespread adoption across many industries, with the fastest growth areas being in e-commerce, food and beverages and healthcare, the report said.

Growing affluence in developing regions such as Asia and the ubiquity of single-use plastic sachets to sell products in small quantities are cited as reasons for growth.

The report also said there is now a growing number of packaging facilities to supply expanding urban populations.

It projects growth of the single-use plastic packaging market despite a growing number of bans on certain types of disposable plastics in key markets such as the European Union, United Kingdom, United States, Taiwan and Hong Kong, as well as heightened awareness of the environmental impact of plastic pollution in the region.

Asia Pacific accounts for the highest market share in global single-use plastics packaging market growth, largely due to the food industry’s growing use of online deliveries to supply customers in markets such as India and China.

A key trend that could shape the future of single-use plastics is healthcare, as providers increase their use of disposables to mitigate cross contamination and infection risk in the wake of the Covid-19 pandemic, the study said.

The report cites the likes of US medical device plastics firm Bemis and New Jersey-based Zipz, which makes wine glasses from polyethylene terephthalate (PET) that looks like classic glassware, as some of the leading market players.

The report emerges two months after research from Minderoo Foundation, a non-profit, found that over the past few years, global production of single-use plastics outstripped recycled plastic production by 15 times.

A further 15 million tonnes of single-use plastic than exists now is expected to be in circulation by 2027 as fossil fuels firms pivot from oil to petrochemicals – the raw material for making plastics – to sustain revenue growth.

The use of plastics as storage materials has gone through many changes over the years since the day it was discovered they could preserve items for long. Over the years, technology has further enhanced that to the point where it is almost impossible to imagine life without these products.

Flexible packaging is one of the most innovative processes to ever come out of plastic packaging. With calls for sustainable packaging solutions, how does flexible packaging position itself for the future? The following are the five facts that cement the belief that flexible packaging is a future long-term solution for all the packaging needs.

Convenience

Life has always been fast and as much as technology is helping ease that, humans are still busy with work and other things; therefore, having to worry about the packaging is their least of their worries. All they want is a long-lasting solution that will handle that part and free them to handle other things. Flexible packaging has done a good job on that end so far, and the same is expected to continue into the future. You’ll be able to dash from work and get ready-made food for the week wrapped in an airtight flexible packaging that can last you days.

Delivery services will also rely more on flexible packaging materials to ensure their products reach their intended target on time and in good condition. This is the kind of convenience that has come to define the flexible packaging sphere, and it will continue to be the case many years from now.

Long Shelf Life

Gone are the days where packaged food had to have a limited shelf life due to inferior packaging options. Canned food, for instance, as much as it has worked well over the years, usually relies on a lot of chemicals just to keep it eligible for consumption as long as possible. These chemicals end up layering the chemical composition and the taste of the contents, and this is not what many people want.

Flexible packaging, on the other hand, is a resourceful method that has nothing to do with adding preservatives. It is a simple mechanism of locking up food in a simple pouch that is sealed tight to the point where nothing can get in and out unless it is opened. This increases the time something can stay on the shelf, and this works perfectly as there’s less food wastage.

High barrier films are examples of flexible packaging methods that have airtight seals and work nicely with highly perishable foods like cheese and jerky, shielding them from moisture and oxygen, doubling and even tripling their shelf lives, increasing the chances of being bought than being thrown out as spoiled food.

Storage and Transportation

When compared to rigid packaging, the space occupied by flexible packaging is very minimal. Take flexible pouches that are sussed for storing juices, they are usually flat in shape and can be piled on top of each other in huge numbers, lying flat against each other, and there would be so much space left for more. When you compare that with normal juice bottles that have to be stored upright, you realize how different the two can be.

Less weight means more can be packed up in a single shipping storage unit, which translates to less gas used to transport them, and this ultimately means that the carbon footprint left behind on account of these types of packaging is minimal.

The storage space on the shelves in shops and supermarkets also benefits greatly from flexible packaging. With rigid packaging, space is determined by the size and the shape of the packaging, not the product itself. Flexible packaging, on the other hand, takes the shape of the product, and this allows more to be stacked on the shelves; this saves retailers money, which could have been used to hire storage facilities.

Customizations

It is easier to add customizations when dealing with flexible packaging compared to rigid packaging. They are flexible and soft in nature, and the material bounces back no after how you squeeze or fold it. This means adding artwork or graphic branding on them is something that can be done even after it has already been manufactured and is ready to use. These branding capabilities enhance the visual aspect of the final product, which in turn increases sales as it can capture the attention of the consumer much faster even when placed on a crowded shelf.

Brand owners looking to give a boost to their products in the future should consider embracing flexible packaging as they are more compatible with all forms of branding technology, be it printing or any other labeling method and software. These are some of the luxuries that rigid packaging cannot enjoy; once it has been set, it becomes impossible to add any modifications afterward.

With more branding tools becoming cheaper and accessible to many people. People in the future are going to be able to handle their own branding without having to pay another individual for it. Accessibility to online software that can create beautiful branding within minutes will be widespread, saving people a lot of money that usually goes into branding.

Unlimited Possibilities

The flexibility of flexible packaging opens up a whole new world of possibilities. There are no limits to how big or how small they can get. The ability to produce them in any shape and size means that literally anything can be packaged with this type, and this is very promising when you consider how fast the manufacturing industry is expected to grow in the next 20 years.

To meet the demands of a growing population against dwindling resources, the need to preserve the little food that is produced has never been so important like this. So far, flexible packing provides the solutions that ensure more food is stored for a much longer period without any alteration to the taste and the quality.

The leading manufacturing companies around the world are currently investing heavily in research and development, creating newer and more refined forms of flexible packaging in anticipation of strict environmental laws that will essentially block any plastic material that is deemed non-sustainable. It may sound harsh, but the developments of alternative solutions to this problem will benefit the consumers as they will now get access to better flexible packaging materials at a much lower price than before.

There’s growing hope that soon, there will be a special type of flexible packaging products that can be reused over and over again without compromising their structural integrity or affecting the safety of the contents they protect.

Introduction

Film & Flexible Plastic Packaging

Film and flexible plastic packaging (‘flexibles’) is the fastest-growing plastic packaging category. Due to their low weight, low cost and high functionality, flexibles are used for many products, such as fresh fruit, meat, dry food, confectionary, drinks and more. The construction may be plain, printed, coated, coextruded or laminated.

As noted by the Association of Plastics Recyclers (APR), the vast majority of film is polyethylene and polypropylene, but currently only polyethylene is routinely collected and recycled as “PCR” (Post-Consumer-Recycled) in North America.

Life-cycle assessments, which take into account the full cycle of packaging, from material extraction to disposal, often show that flexibles are preferred, when compared with alternatives. However, flexibles are typically single-use, with very low recycling rates, and some flexible formats, such as food wrappers and plastic bags, are high-frequency litter items.

Definition

A 2021 Recycling Partnership white paper provides these definitions:

Film: Plastic film is typically defined as any plastic less than 10 millimeters thick. The majority of plastic film is made from polyethylene (PE) resins, both low-density and high-density materials.

Examples include retail grocery bags, bread bags, produce bags , air pillows and case wrap. Polypropylene (PP) is also used for packaging in similar applications. These film categories are often referred to as “monolayer” film.

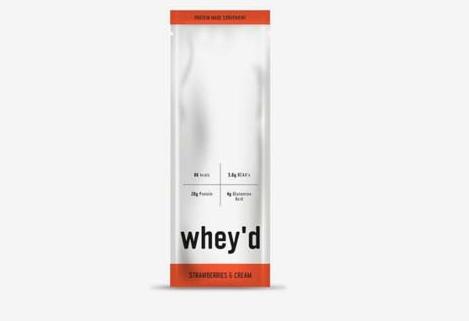

Flexible packaging: In contrast to monolayer film, flexible packaging is often comprised of multiple materials or multiple layers of plastic film. The different properties in each layer contribute different performance characteristics to the package. The layers within a flexible package can be aluminum foil or paper in addition to plastic.

Examples include pouches, sleeves, sachets, and bags.